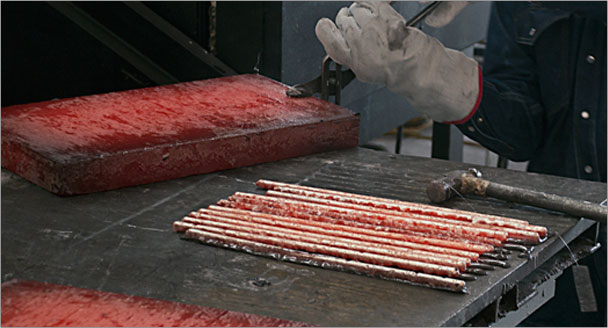

Dynalloy Industries manufactures premium quality Dynarod Tungsten Carbide composite brazing rods. They are used in a variety of applications which involve milling and cutting, as well as wear resistance. Dynarod provides weld deposits consisting of layers of multi-faceted chips of Tungsten Carbide in a Nickel Silver, Nickel/Chrome/Boron, or Silicon Bronze matrix. Dynarod is offered in three different grades, “S” grade for cutting steel, “R” grade for cutting rock, and “W” grade for enhanced wear resistance. Dynarod is also offered in two different diameters, Standard for covering larger areas, and Micro for smaller geometries.

DYNAROD NCB

Blocky Tungsten Carbide chips cast into rod form with a wear resistant NiCrB matrix. Blocky particles are less sharp, but perfect for uses with extreme abrasion, as the shape allows the crushed carbide to pack tighter and ultimately reduce wear. Matrix hardness is 45 Rc.